As a rule, last-mile delivery of heavy trucks is largely penetrated by the view of the “easy” stage. The distances are shorter, the routes are well Known, and the drivers are close to the terminals or their home bases. Nevertheless, the last mile statistically and in regard to operations is the most dangerous part of the trip for heavy trucks. The ever-tightened urban spaces are mixed with the numerous complicated traffic arrangements, loading docks, pedestrians and constantly moving vehicles that LA last-Mile delivery becomes a concentrated risk area.

Compared to speed and distance, heavy trucks depend more on the driver’s preparation, consistency and attention to detail to deliver the goods without damage or injury. On the other hand, a failed inspection that might have gone unobserved while driving on an open highway may lead to a serious accident in a highly congested delivery zone. For this reason, a structured safety checklist is not an optional item; it is a part of the profession truck driving.

A consistent safety checklist transforms routine vehicle safety checks into a defensive layer against urban delivery risks.

The Auto-Safety Checklist for Heavy Truck Last-Mile Delivery has been detailed in this article. It is made up of three parts: the vehicle state, driver readiness and operation awareness. It is not compliance for compliance’s sake; it is simply risk prevention where it matters most.

Why Is Last-Mile Delivery a High-Risk Zone for Heavy Trucks

Medical Delivery Weight is the weight and the qualities of the vehicle and the environment. The environment was not intended for heavy usage. Streets are narrower; curbside parking is available; signs break visibility; people walk, and traffic gets more difficult with everything from cyclists enjoy the road and impatient local traffic to living conditions where tiny errors can add up to accidents very quickly.

In contrast to long-distance driving, last-mile delivery includes:

- Broken coast cables and windsocks on the way

- Decisions not to brake

- Turning at a sharp angle

- Loading or unloading at docks and/or alleys

- Cabbing in and out

- Interfacing with local traffic

All of these factors cumulatively increase the possibility of accidents, property damage, and driver injuries. A robust fleet safety culture acknowledges that last-mile tasks entail added checks, not decreased ones.

This is why focused vehicle safety checks are more critical in the last mile than during long-haul highway segments.

Critical Vehicle Systems for Last-Mile Safety

| Safety Area | Why It Matters in Last-Mile Delivery | Primary Risk if Ignored |

| Brake system | Frequent stopping in traffic and docks | Rear-end collisions, dock impact |

| Tires | Curbs, potholes, uneven pavement | Loss of traction, blowouts |

| Steering system | Tight turns and low-speed maneuvers | Inability to control vehicle path |

| Visibility equipment | Pedestrians, cyclists, blind zones | Low-speed injury incidents |

| Engine & cooling | Repeated starts and idling | Breakdowns in urban traffic |

The Significance of a Truck Inspection Checklist in Maintaining Last-Mile Safety

The Essential Trucking Checklist You Absolutely Need

A truck inspection checklist is a structured way that helps in avoiding the potential risks. The delivery of the last mile focuses only on the systems constantly under stress: brakes, tires, steering, and visibility components.

A routine pre-trip inspection should not be hurried just because of a short routing. On the contrary, a short route is more impactful because it leads to more mechanic cycling and opening up weak points faster than steady road driving.

A detailed safety checklist ensures that repeated short runs do not bypass essential vehicle safety checks.

Vehicle Safety Checks: Exterior Inspection

Brake System Check

The brake system of a truck is a single most important safety factor when it comes to the last mile delivery. The frequent stops at urban traffic generate the heat, wear, and fatigue on brakes faster than they would on a highway.

The brake system should receive a thorough check that includes:

- Inspection of brake lines and hoses

- Listening for air leaks

- Confirming proper air pressure build-up

- Testing brake response before entering traffic

Poor brake performance in the last mile areas not only the reaction margin but also increases the risk of an accident at the docks and cross roads.

Tire Pressure and Tire Condition

Tires are the full operational load of the vehicle while, at the same time, they absorb the impacts of the constant curb, potholes, and uneven pavement. Incorrect tire pressure does affect the distance of stopping, the precision of steering, and the stability of the vehicle.

The most important observation of tires:

Pressure set according to the manufacturer’s specifications

No visible sidewall damage or bulging

Adequate tread depth to prevent aquaplaning on wet conditions

Using similar tire types on the axles, when feasible

Vulnerabilities in tires introduced by the delivery route are very unlike the freeways causing gruesome trouble spots by making tire inspections imperative to heavy-duty trucks.

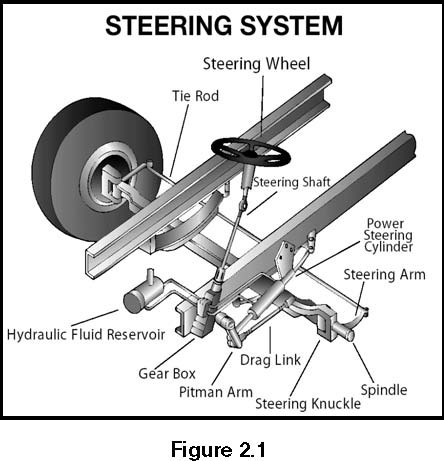

Steering System Inspection

Urban maneuvering demands are always placed on the steering system. Any looseness, vibration, or delayed response creates danger in restricted areas.

A complete steering check should include:

- Steering wheel play check

- Power steering fluid level inspection

- Clearing up leaks or damaged hoses

- Low-speed turn response should be smooth

Steering issues do not ease in a route; rather, they worsen under the pressure of repeated maneuvering.

Engine Health and Under-Hood Inspection

Even short-distance runs make full engine reliability mandatory. Last-mile operations generally consist of a high number of starts, idling, and low-speed operation of the vehicle; therefore, they stress cooling and lubrication systems.

Engine health checks should be made of:

- Oil level and state

- Coolant level and leak detection

- Belt and hose conditions

- Warning lights and fault codes

Monitoring engine health during last-mile delivery prevents breakdowns in high-risk urban environments.

A vehicular malfunction in the last mile not only delays the freight but also block traffic, create hazards on the road for others and poses a risk to the drivers.

Equipment Inspection for Last-Mile Operations

Mirrors, Cameras, and Visibility Aids

Sometimes it becomes very difficult to see in congested delivery areas. The blind spots take little time to expand when pedestrians and cyclists strike without the driver’s perceived path.

A good equipment check must include:

- Clean, properly set mirrors

- Backing-up cameras, and sensors are working

- Operational turn signals and hazard lights

- A clear windshield and functional wipers

Regular equipment inspection is essential to maintaining visibility and situational awareness during last-mile delivery.

Last-mile delivery incidents occur mainly at a low speed, where it is not the speed, however, about visibility that dictates the outcome.

Cargo Securement and Door Systems

Frequent stops up the chances of cargo shift. Minor movements affecting the balance of the vehicle and the safety of unloading.

Checklist items:

- Load securement devices intact

- Doors opening and closing smoothly

- No loose freight near access points

- Dock plates and lift gates functioning correctly

A cargo shift in a tight turn or a sudden stop can throw a heavy truck, thus, being dangerous to on top loads.

Driver Safety Readiness

Physical and Mental Readiness

Last-mile delivery can be quite exigent in cognitive capacity. Constant decision-making, navigation, and situational awareness create cognitive fatigue faster than highway driving.

Driver safety checks should include:

- Adequate rest prior to shift

- Hydration and nutrition status

- Mental focus and stress level

- Awareness of route complexity

Driver safety depends on readiness as much as mechanical condition during last-mile operations. Even a little tired driver congested area multiplies the risk, even with low speeds.

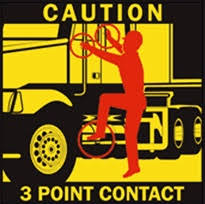

Cab Safety and Exit Awareness

Drivers exit and enter the cab frequently during last-mile delivery. Many are not aware that many injuries occur not while driving, but during these transitions.

Cab safety checklist:

- Three-point contact maintained

- Non-slip footwear

- Clear steps and handholds

- Awareness of surrounding traffic before exit

Driver safety includes everything from steering control to stepping down safely at delivery points.

Risk Concentration in Heavy Truck Last-Mile Delivery

| Risk Source | Typical Highway Driving | Last-Mile Delivery Environment |

| Driver fatigue | Gradual, predictable | Rapid cognitive overload |

| Mechanical stress | Even and sustained | Repeated start-stop cycles |

| Visibility challenges | Limited but stable | Constant blind spot changes |

| Decision frequency | Low | Very high |

| Injury likelihood | High-speed incidents | Low-speed, high-frequency incidents |

Commercial Vehicle Inspection Compliance

Drivers are not exempt from commercial vehicle inspections in the last-mile delivery. This is especially true as scrutiny is often more prominent in urban zones.

Routine compliance checks reinforce:

- Regulatory adherence

- Fleet accountability

- Consistent safety behavior

- Reduced liability exposure

The structured safety checklist keeps drivers beyond inspection-ready always, not only during the audits.

Fleet Safety and Organizational Responsibility

Why Fleets Must Prioritize Last-Mile Safety

The fleet safety is not built solely on the highway miles. Urban deliver incidents carry more liability, reputational damage, and injury risks.

The fleet works effectively by employing the following:

- Standardized safety checklists

- Training specific to last-mile delivery

- Preventive heavy-duty truck maintenance schedules

- Open reporting of safety concerns

The safety culture must reflect where the risk is highest and not the area where the miles are longest.

Using Safety Checklists as Living Tools

The checklist for safety needs to be operational and in real-time. As routes change, vehicles get older, and delivery environments also change.

Best practices include:

- Updating checklists based on incident data

- Encouraging driver feedback

- Reinforcing checklist use through training

- Treating checklists as risk tools, not paperwork

Safety checklists are, if used correctly, a sure way to protect the driver, freight, and the public.

Final Thoughts: Safety Is Concentrated in the Last Mile

Last-mile delivery compresses risk into short distances. Heavy truck safety in these environments depends on discipline, repetition, and attention to detail. A proper safety checklist transforms routine inspections into a defensive system against preventable incidents.

Each brake system check, tire pressure verification, steering system inspection, equipment review, and engine health assessment contribute to better operations. Driver loading is reinstated, not by fast moves, but by being well prepared. The fleet safety is improved when the organizations accept that the last mile is not the easiest mile. It is, in fact, the hardest one.

In heavy truck operations safety is not rated by the length of the distance you drive, but by how cautiously you drive where it is necessary the most.

Last-mile risk isn’t only traffic and blind spots — cargo protection and liability also matter. This explains shippers interest insurance and why it’s relevant even for smaller carriers.